Food & Beverage: IO-Link portfolio in Process Automation

Increase your efficiency and your 'Overall Operations Effectiveness' by optimizing the processes with the help of IO-Link technology

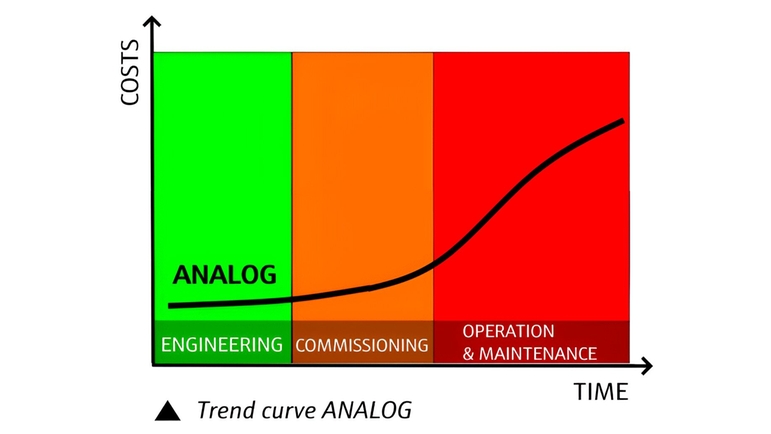

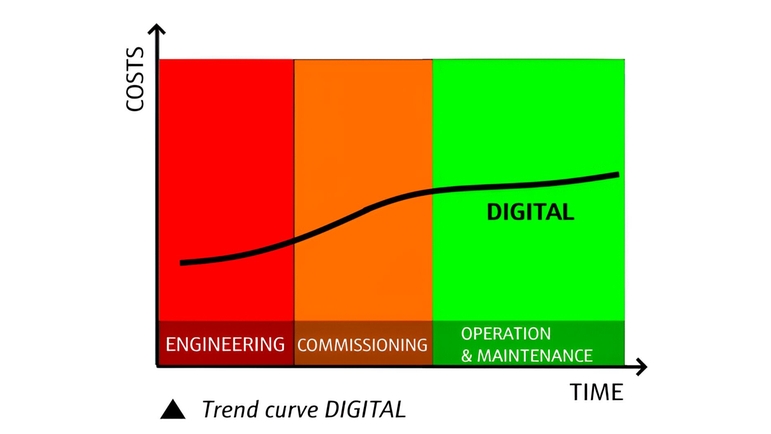

The Food & Beverage industry is facing many challenges, such as stricter compliance regulations, lacking qualified staff and increasing costs for energy, etc. Most of our IO-Link devices can significantly contribute to overcome these challenges. IO-Link is a perfect entry into the world of digitalization to enhance the efficiency of processes and level up your analog device experience. Start your digital transformation process with the unique Endress+Hauser IO-Link product portfolio.

Benefits

Fit-for-purpose IO-Link instruments, especially for skid builders, with outstanding quality for process automation

Most Endress+Hauser IO-Link devices have hygienic approvals and can operate under harsh conditions (Ingress Protection)

Measuring points that were previously not available for IO-Link technology in process automation are now part of the Endress+Hauser product portfolio

High-level of interoperability with third-party IO-Link Master's and IO-Link configuration software tools achieved through a standardized and deep-level implementation of the Smart Sensor Profile

Fast and easy device integration into leading Process Control Systems thanks to the free-of-charge Integration Software Package (Function Block Libraries)

High degree of standardization

The Endress+Hauser IO-Link devices are highly standardized, attractively priced, and deliver an added value by offering an extended device status coming with the cyclic process data. We have implemented our devices according to the latest specifications of the official IO-Link community. Our portfolio has exceptional quality with high interoperability, and even offers a flexible operation mode on most IO-Link instruments (digital/analog), so customers can switch to digital operations later on.

IO-Link Product Portfolio

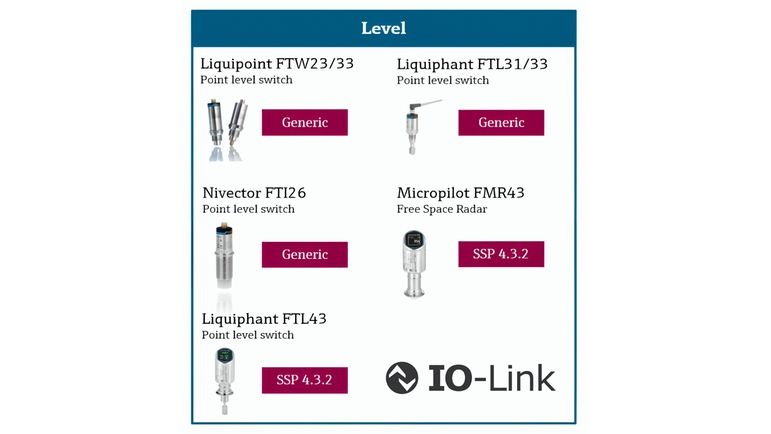

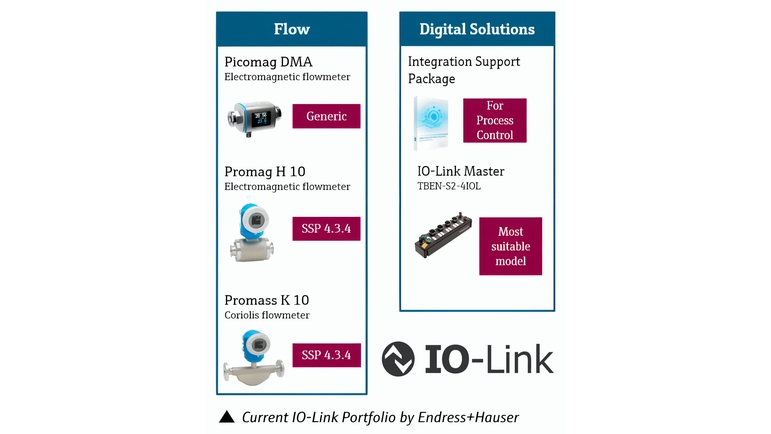

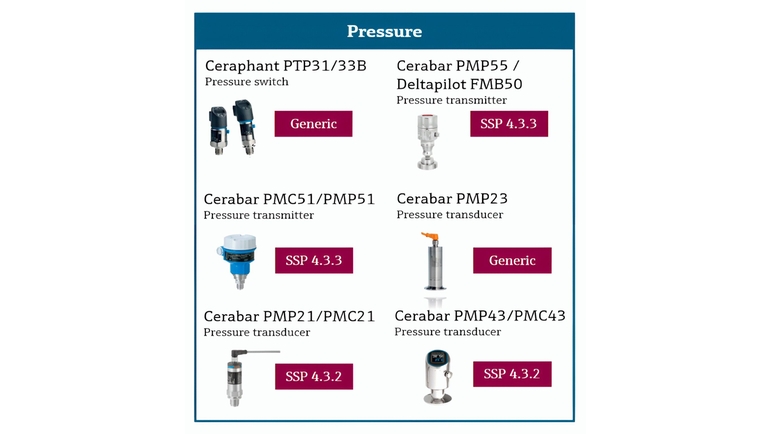

We provide IO-Link capable devices for all relevant parameters in Process Automation:

Pressure: Cerabar PMP23, Ceraphant PTP33B

Level: Liquipoint FTW23/33, Nivector FTI26

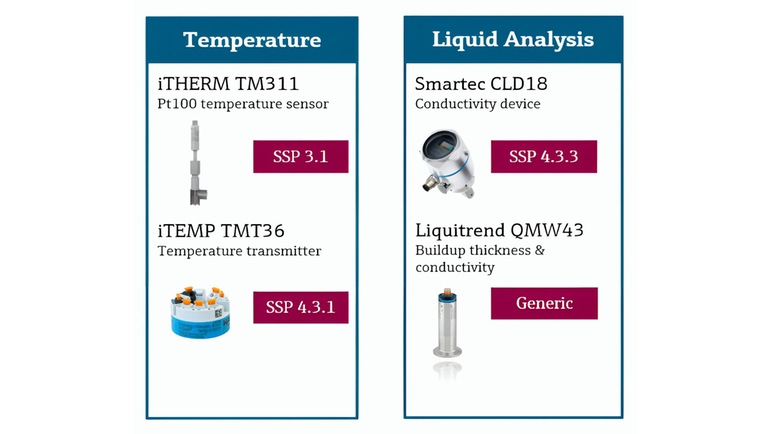

Temperature: iTHERM TM311

Liquid analysis: Smartec CLD18

The highly standardized IO-Link devices are shipped with best practice presets for the Food & Beverage industry. Parameters can be changed with the Endress+Hauser free software DeviceCare and with the FieldPort SFP20.

More IO-Link products:

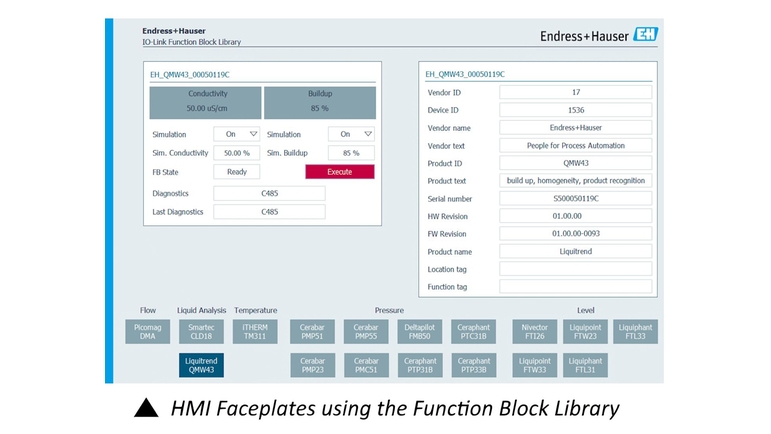

Pressure: Cerabar PMP23, Ceraphant PTP33B, Deltapilot FMB50/55, Cerabar PMP51, Ceraphant PTP31B, Cerabar PMP43

Level: Micropilot FMR43, Liquiphant FTL31/33

Temperature: iTEMP TMT36 , iTHERM TM402/TM412

Liquid Analysis: Liquitrend QMW43

IO-Link Integration Software Packages

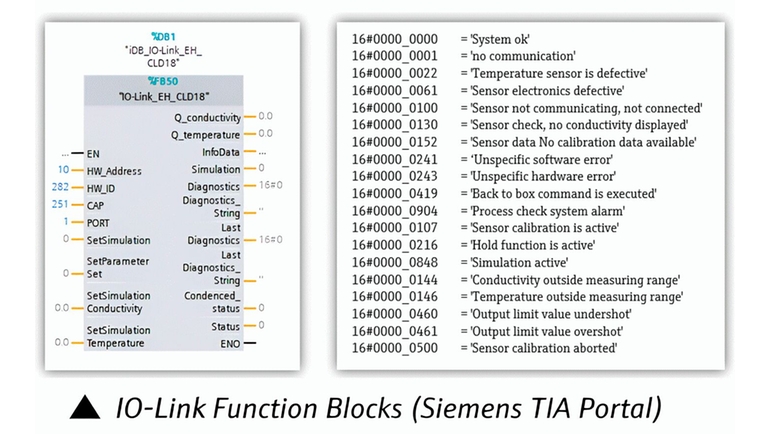

The suitable software library is provided to facilitate an easy and seamless integration of the Endress+Hauser devices into the process control system. The free-of-charge software package contains function blocks and matching HMI faceplates for the Siemens TIA Portal and for the Rockwell Automation PlantPAx.

IO-Link Master

Endress+Hauser partnered with TURCK to offer Open Integration and a high performance IO-Link Master. The IO-Link Master Module (TBEN-S2-4IOL) supports the Endress+Hauser IO-Link devices through its SIDI functionality and the CommDTM driver enables access to the Endress+Hauser FieldCare.

The model also works perfectly in combination with the Endress+Hauser IO-Link Integration Support Package.

IO-Link Starter Kit

The affordable IO-Link allows you to convince yourself of easy device handling. You also get to see extra advantages when choosing the IO-Link equipment from Endress+Hauser. The IO-Link starter kit consists of an Endress+Hauser temperature sensor, an IO-Link master, and necessary connection and power supply cables.

TM311

IO-Link Master

Standard cable

Software function block for Siemens TIA Portal